Bra Physics 4 - What can we learn about the cups and straps?

In this part, I talk about the physics involved in the cups and the straps. The cups are by far the most complex part of the bra, and their geometry befuddles millions of people worldwide. I won't be talking about geometry here - cup shape, strap positioning, and necklines (well, I do a tiny bit in the extended version), but instead your material choice and how it impacts a bra.

You can check out part 1 where I go over the main function of a bra and the forces it needs to provide. part 2 discusses the design of the band, part 3 the wires and cradle.

As before, an extended version of this post can be found on my Ko-fi, where you can get instant access to this and previous extended blog posts for just £2/$3. If you want, you can then continue subscribing on a monthly basis to support my blog.

Stress and Strain - A Recap

The strain of an item is essentially how much its length has increased, as a proportion of its original length. If your bra band measures 30" on the table, and you put it around yout 33" underbust, you have created a strain in the fabric of 3/30 = 0.1 (strain has no units). If we strain a material a little bit, the deformation (ie change in length) is elastic and thus reverses as soon as we stop applying force. If we strain it too much, the deformation becomes plastic and the material is

permanently deformed.

The

stress within an item is related to the force that you put on it.

Stress is a quantity within a material that occurs when you transmit a

force through that material. Stress is defined as the force transmitted

through a surface divided by its area.

When

you wrap a bra band around yourself, you are applying force to make it

strain. If your bra band is made out of a stiffer material, more force

will be required to strain it to the same degreee. This increased force

will result in higher internal stresses in the bra fabric. To maximise

material longevity, we should aim to reduce stress in all areas of the

materials.

When

a bra sits on you, it applies forces to you, spread out over various

contact areas. If the contact area for a certain force is small, the

stress on that part of your body is higher and the bra is more likely to

cause pain or injury. For maximum comfort, we should aim to minimise

stress on all areas of our bodies.

Stretch and Recovery - A Recap

In Part 2 of this series, I talked about how the engineering concepts of stress and strain are related to the fabric concepts of stretch and recovery. It's important to bear in mind that the information you get about fabric when purchasing online may not be very helpful in determining how suitable they are for bra making:

- The absolute stretch percentage of a fabric does not show how much force is needed to reach that percentage, and thus how much your bra will be able to resist this stretch and apply force against your breasts

- The stretch percentage does not tell you whether you are elastically or plastically deforming your fabric, and thus how much your bra will be able to spring back

- The stretch percentage does not show if your material is resistant to creep, if not it will easily stretch out with wear.

All of these concepts apply to cup and strap materials, and should be considered in addition to the information shared below.

Straps - How should they be designed and why?

As discussed in my previous post, the straps are mostly there to provide a vertical force to support the upper cup, where the wires don't have an effect.

The

amount of force a strap can provide before failing is related to its

material and width. The comfort of a strap is also related to its material

and width.

Narrow vs wide straps

I'm sure you already know this: wider

straps can transmit more force than narrower ones, so are more supportive full stop. Additionally, they have a larger area of contact on

the shoulder, reducing the stress on your shoulder and increasing

comfort. There's a reason why wider straps are so popular in larger cup

sizes.

Elastic vs fabric straps

Straps

are typically made out of firm elastic, though some are made out of

elastic lined fabric. Fabric straps, naturally, do not stretch as much

as elastic.

While elastic straps are popular and fast to sew, they come with some drawbacks. The first is wear - elastic straps will stretch out over time (known as creep), and those making supportive bras for heavy busts will have to take some care to find elastic that is firm and durable enough to withstand use. The second problem comes with everday usage: when you move around and your breasts bounce, straps will stretch and oscillate in response, causing jiggling in your breasts. This is known as an underdamped response, with your breasts moving for some time in response to a single movement (such as a footstep or a jump). Sturdier straps - ie those that strain less with a given stress - will, as you probably intuitively know, reduce the amplitude of the oscillation (i.e. the amount which your boobs bounce) and thus keep your boobs from jiggling as much.

Additionally, elastic straps can stretch unevenly, curving at the shoulder, which concentrates the load of your breasts on a smaller point than intended, increasing the stress on your body.

Fabric straps are frequently used by large cup designers to get around these two issues, but these aren't perfect either. Fabric straps are sometimes lined with foam to increase comfort, and are characterised by their rigidity - under increased breast forces, the fabric won't stretch out much. This will reduce that oscillation caused by elastic straps. However, this is a double edged sword, as fabric straps will resist all movement, potentially restricting arm and shoulder motion. Body changes throughout the day can also make rigid fabric straps uncomfortable. Another potential issue is, during running/bouncing, the straps can apply force very quickly to your shoulder instead of it slowly building up, which can be very uncomfortable.

An option that many sports bra manufacturers go for is a strap partially made out of elastic, and partially out of fabric. This will reduce the bouncing associated with entirely elastic straps, but should still allow for arm and shoulder movement.

The

placement of straps - narrowly or widely - is also important when it

comes to directing forces through the cups, and I have a

post that goes into a bit more detail about this, but I don't talk about different strap designs in that one.

Racerback/Cross-Back Straps

I originally had a whole bit written about racer-back/cross back straps and their efficacy in daily bras and sports bras, but it was taking over the whole post. So I'll be moving the analysis of these different back designs to an entirely new post, as this particular area is pretty interesting and there's lots of design variations to think and talk about. When the post has been published I'll be sure to link to it from here.Cup Materials

More

rigid materials like Sheer Cup Lining (stabilised nylon/marquisette) and Duoplex (stable polyester tricot) will maintain their

shape more when worn (ie, will strain less), allowing for more supportive bras. However, a bra can be designed around the strain of the cup fabric used - switching from a slightly stretchy fabric to a completely rigid fabric (and vice versa) without adjusting the pattern can often cause fit issues because of altered cup tension and cup geometry.

Stretchier

materials with high recovery like powermesh can still be supportive in the cups as

they will resist the forces of your breasts but will provide less

shaping. Stretchy materials with low recovery such as stretch lace and

cotton jersey will provide the least support overall and are more likely

to be pushed out of shape by your breasts.

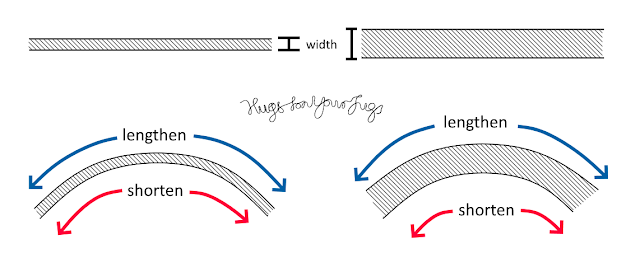

Foam for Bra Cups

Bra

foam is an interesting material - it typically has low stretch, but because of its thickness it also has low flexibility in the 3D plane.

This is because for a piece of fabric material to bend, it must compress on the inside and

stretch on the outside. Thinner materials need to stretch less (and thus

have an easier time) when going around curves because the radii of the

curve for the inner and outer edges are very similar.

This makes it harder for a foam cup

to flex to better suit your breast shape, but better at maintaining its

shape. This makes foam a popular choice in strapless bras, as the upper

cup maintains its shape quite well.

Foam

is less suitable for very full (including true omega) shapes, because

the low 3D stretch means that it has a more difficult time jutting out

from the wireline at sharp angles.

Stretch materials for sports bras?

Note that, just like with the straps, stretchy materials can increase bouncing and jiggling with movement. So why are they so popular with sports bras?

Stretch cup fabrics are most popular with compression based sports bras, where the cups stretch around you to compress your breasts against your chest. This essentially "takes up" the potential stretch in the fabric - it reaches its elastic limit - making sure it doesn't stretch further. Additionally, in a compression based sports bra your breasts are held flatter against your chest and compressed down, reducing the amount of jiggling they can undergo.

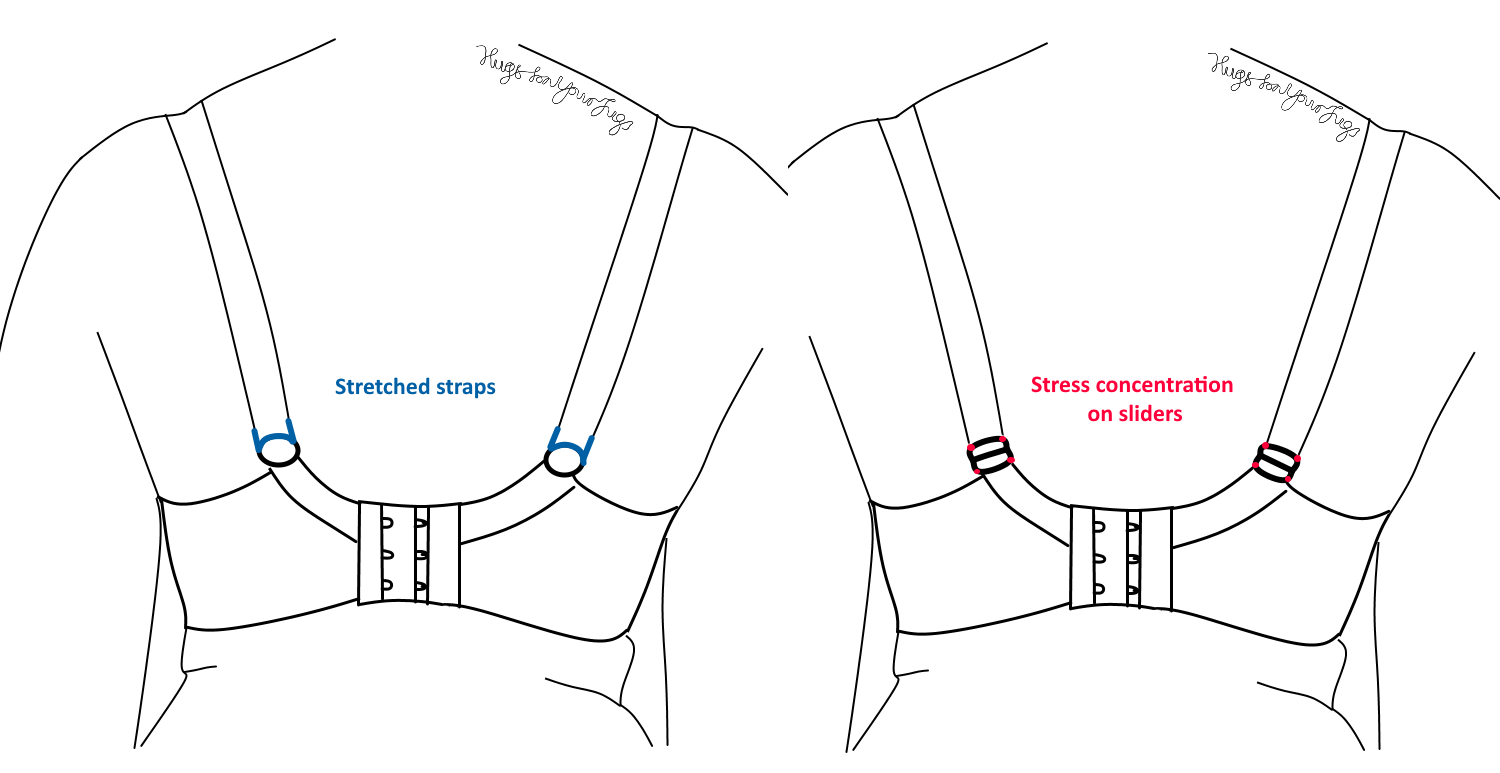

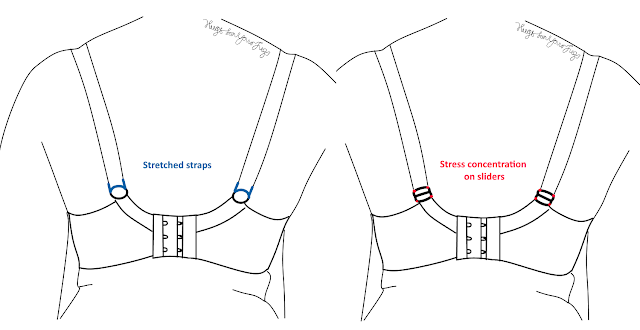

Rings & Sliders

Most bras feature straps that are sewn onto the cups at the front, and have sliders for adjustability, and have rings in the back to attach them to the band at the back.

Sometimes, however, bras feature an additional slider as the back strap attachment point.

Aside from the fit benefits of using a ring - the strap can more easily change its angle of attachment to suit different bodies - are rings or sliders better to use from a structural perspective?

Rings are extremely strong shapes, so even a plastic ring will probably not fail when used in a bra. This is because there are no points in the ring where stress can be concentrated (usually happening at corners), but a slider has stress concentration points at each bend and plastic ones can break here. Despite this, I personally am not a huge fan of rings on my bra because I don't like how they misshape the strap elastic over time, stretching it out more at the edges. Metal sliders will always be my preference for attaching straps at the back, as they rarely break and do not affect the strap elastic.

In the extended edition of this post, I talk about the position of your bust apex and how that affects band tension. If you would like to read this, you can access it (and all other extended editions of my posts) for just £2 on my Ko-fi.

Comments

Post a Comment