Bra Physics Part 2: What Can We Learn about the Band?

In my last bra physics post, I described the forces involved in supporting your breasts and what parts of a bra are responsible for providing those forces. How can this knowledge inform our decisions when making or choosing bras? This post is part of a series and covers the bands of bras - just the stretchy part. The cradle (which surrounds the wires) will be discussed later.

I'm sure a lot of this information will be things you already know, we all have a very intuitive understanding of forces and most of us have lived experiences of wearing bras. I'm hoping this blog post can scientifically reinforce knowledge you already have, improve your understanding, and potentially introduce you to some things you haven't thought about before.

While before I talked about how the band provides the horizontal and vertical forces in a bra, working to support your breasts, this is not the entire story. The band provides these forces by working with your body, but there is a sort of "chain of support" within a bra. The band providing these forces does not help support the breasts if the band does not transfer these forces to the cradle, and the cradle to the cups, so the cups can counteract the forces of the breasts. To create a supportive bra we need to ensure that all of these components are functional, otherwise, it's essentially wasted effort.

But that's getting ahead of ourselves: today we are discussing the band. Before we do so, however, I want to introduce you to the engineering concepts of stress and strain and how they relate to the fabric concepts of stretch and recovery.

Stress and Strain

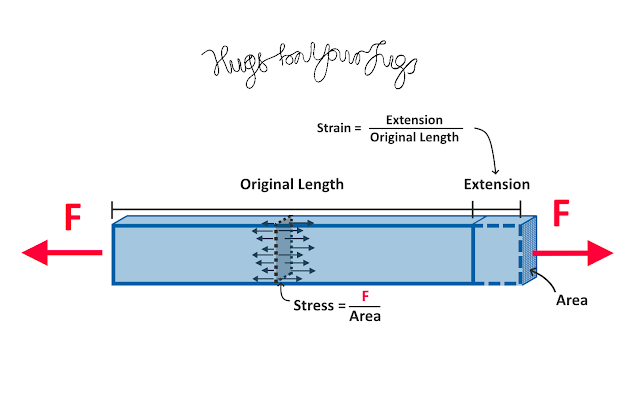

The strain of an item is essentially how much its length has increased, as a proportion of its original length. If your bra band measures 30" on the table, and you put it around your 33" underbust, you have created a strain in the fabric of 3"/30" = 0.1 (strain has no units).

The stress within an item is related to the force that you put on it to strain it. Stress is a quantity within a material that occurs when you transmit a force through that material, as the material resists straining. Stress is defined as the force transmitted through a surface divided by its area. Wearing a stiletto in mud is a bad idea and causes you to sink, because the small contact area of the heel causes high stress on the mud, and you fall in.

|

| Stress and Strain |

Elastic deformation: If we strain a material a little bit, the deformation (ie change in length) is elastic and thus reverses as soon as we stop applying force. When elastically deforming a material, strain is proportional to stress. That is, doubling the stress will result in doubling the strain.

Plastic deformation: Straining a material too much causes the deformation to become plastic. It is permanently deformed. Think of a paperclip If you bend a paperclip just a little, it springs back into shape. This is elastic deformation. But if you bend it too much, it's now entirely the wrong shape - it has plastically deformed.

|

| Elastic vs plastic deformation |

Stress applies in tension too. The stress in this board is not equal along its length, because even though the force is the same throughout the board, in the centre it is being distributed across a much smaller area.

|

| Stress is dependent on area |

When you wrap a bra band around yourself, you are applying force to make it strain. If your bra band is made out of a stiffer material, more force will be required to strain it to the same degree. This increased force will result in higher internal stresses in the bra fabric. To maximise material longevity, we should aim to reduce stress in all areas of the materials. This goes for all parts of a bra, not just the band.

When a bra sits on you, it applies forces to you, spread out over various contact areas. If the contact area for a certain force is small, the stress on that part of your body is higher and the bra is more likely to cause pain or injury. For maximum comfort, we should aim to minimise stress on all areas of our bodies.

How Stress and Strain Relate to Stretch and Recovery

If you are a bra maker, I'm sure you have thought from time to time "why couldn't I make a bra out of jersey? Or bias cut fabric? Those things stretch to the 40% or so required to make a bra." The answer to that is a fabric concept called recovery.

When we apply force to strain a fabric, that force affects the fabric differently depending on fabric type. For woven fabrics and fabrics without a lot of elastane, this force is used to permanently straighten out/realign the fabric fibres. These fibres do not store this energy, and so when you release the stretch the fabric does not snap back into shape. In fabrics with elastane, the energy is stored within the fibres themselves during the stretch, and is used to return the fabric to its original shape.

From an engineering perspective, fabrics without a lot of elastane only have a small capacity for elastic deformation (the idea of stretching a fabric and having it bounce back to normal). Fabrics without elastane tend to plastically deform, that is, permanently stretch out to that new length and not bounce back when the force is removed. In either case, a material's resistance to further strain (ie further stretch) is the tensile force it can provide.

The concept of fabric recovery also covers another engineering concept called creep. Many fabrics, but especially non-elastane-containing ones are very susceptible to creep. Creep is the permanent lengthening of a material when under stress (despite the material supposedly being elastic at this level of strain). Creep occurs over time, so the longer a fabric is held at stress, the more it will deform.

This section of powermesh easily strains elastically from 15cm to 25+cm. However, holding it at 20cm for just one minute has caused it to creep 1mm.

So while a fabric that you may be considering to use for a band may be listed as having 30% maximum stretch, if that stretch is not accompanied by elastic recovery and resistance to creep, that stretch has limited use as a supportive part of a bra.

Additionally, some fabric may strain a lot with a small amount of stress applied. Usually, these fabrics are accompanied by listed stretch percentages of 50%+. This is common in lightweight powermeshes, jerseys, etc., and again these are less useful in bra making because of how much you need to strain (i.e. stretch) them to have a high tensile force, even if they do have good recovery. Their high strain makes the garment harder to sew, as your fabric pieces will be smaller and change shape a lot more.

But what does 60% stretch even mean? Fabric stretch percentage is a very arbitrary measure, and is usually ascertained by someone pinching the fabric, stretching it until the fabric resists further pulling quite strongly (but not necessarily entirely to this point), and then measuring how much it has stretched.

What stretch percentage may tell you is the maximum (or near maximum) amount of strain before a fabric plastically deforms - stretching out permanently or even ripping. When you are stretching a material and are nearing the maximum elastic strain (also known as the elastic limit), the material will begin to behave differently and (usually) requires a lot more force to strain further. This can feel like an end to the stretch, but transitioning from elasticity to plasticity is more of an end to recoverable stretch, and the beginning of permanent deformation of the fabric.

Stretch percentages on fabric, though very common, are not very useful metrics in bra making. Not only is recovery not included, but it doesn't tell you how much tension a fabric can withstand, i.e. how much force is required to get it to that 60% stretch. Furthermore, unless you are reaching the limits of elastic deformation, the length to which a piece of fabric stretches entirely depends on the force applied and fabric width.

Remember stress being force / area? When you stretch a fabric, you are distributing a certain force across its entire width. The "area" in this case being the very thin cross-section of the fabric - the area is the width of your fabric piece multiplied by your fabric thickness (w*t = A). If you double the width of the fabric piece you are testing, the area is 2w*t = 2A.

|

| The relevant "area" of a piece of fabric when we strain it is that of its cross section |

What this means is that if you apply the same force to a double width of fabric, you are reducing the stress by half. If the fabric is elastically deforming, you will therefore reduce the strain by half (because stress is proportional to strain), and the fabric will stretch to only half the amount that it did before.*

Similarly, if you double the thickness of the fabric by layering it, the area is w*2t = 2A. You may also want to think of this as doubling the width of your fabric and then folding it in half - either way, the result is the same.

In this demonstration (I couldn't get footage so you'll just have to trust me), I used the bulldog clips to distribute a force evenly over a certain width, stretched the fabric, and used a luggage scale to determine the force applied. The fabric clips are half the width of the bulldog clips. 0.1kg of force (about 1 Newton) is needed to strain this 18cm sample to 21cm with a fabric clip, but with a bulldog clip we need 0.2kg (about 2 Newtons).

We can use these relationships to our advantage, but it shows that stretch percentage isn't really a useful measure without additional information.

Recap: How a Band Works to Support Your Breasts

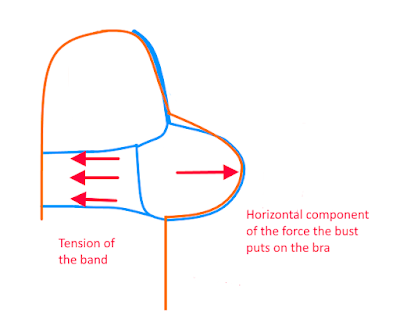

In Part 1, I showed that a band can provide both horizontal and vertical forces to fully support your breasts. It provides horizontal forces through the tension of the band directly, holding the bra against your body.

|

| The tension holds the cups against your chest and compresses your breasts slightly to give a rounded shape |

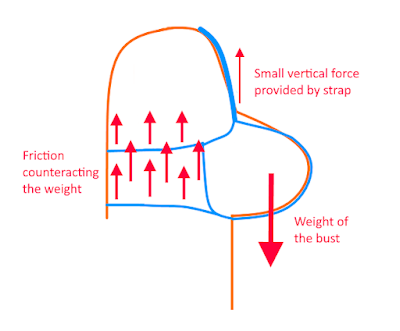

The vertical forces are provided through friction. A band is elastic and squeezes in on your torso, and your torso puts a force on the band to resist this. The force your torso puts on the band is called a normal force, and the friction a band provides is proportional to this. More squeezing = more normal force = more friction = more vertical support.

|

| Your body resists the snugness of the band, providing a normal force. |

|

| Friction is what's providing the lift |

Ideal Band Stretch - Bras vs. Corsets

Is stretch really that important at all? Corsets don't have stretch in them and do a fine job of supporting the bust!

Well, yes and no.

Stretch itself is not an important quality in supporting the bust, it's true. Tension is. Rigid fabrics can do a fine job of supplying tension, and do so without stretching out all over the place like spandex.

In a corset and in a bra, the tension is supplied by the garment being physically smaller than your body, displacing your flesh, and your body resisting your flesh being pushed in. A corset needs to be very tight because, otherwise, it is not under tension. A bra needs to resist stretching around you because, otherwise, it is not under tension. **

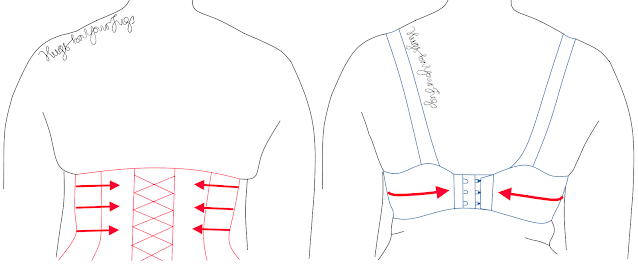

|

| Both of these garments are under tension |

In a corset, however, the corset maintains its shape and the body does not - your body pushes out against the fabric and this causes a normal force coming out of the corset and tension within it.

In a bra, your body by and large maintains its shape, this resistance to deformation causing a normal force in the bra. The fabric has tension in it because it is stretching around you. It's a very minor difference, and really both bras and corsets have an element of both of these in most people.

The need for stretch in a bra comes entirely from the desire for comfort and a smoother silhouette. Because a bra's band is much narrower than a corset, it puts higher stress on your body to provide the same supportive force. A bra band made entirely out of corset fabric that squeezes your ribs into shape would likely be very uncomfortable as it would be very tight and have no flex for moving or breathing.

|

| A corset as narrow as this would have to be very tight to produce the required normal force needed to support a heavier bust |

Adding stretch to the fabric allows you to breathe and your body to change shape throughout the day, and also reduces pressure points, however, increased elasticity will mean that the fabric will have to be cut shorter to provide the same tension. A very stretchy band may reach its elastic limit before appropriate tension is created, and then begin to function more like a corset when worn like a bra.

Appropriate band design is therefore all about finding the right balance between:

a) Having the band be able to strain (stretch) around you enough to provide adequate tension

b) Having enough further stretch when worn to be comfortable and reduce pressure points

( & c) Not be stretched near to its elastic limits to preserve longevity)

Band Design Considerations

The band holds the cradle and wires firmly against the body to support the cups, which in turn support your breasts. We've learned that the band needs to be snug but not overstretched, comfortable but not under strained. How can we use these principles to design more supportive bras?

- In a bra, if the fabric is too stretchy - it strains a lot with little tension - then it cannot do its job well. Additionally to this, if you use a woven fabric that plastically deforms, or an elastic fabric that has been overstretched, the band will become the same length as your underbust is, and then no further stretch will be required and the bra will not be under tension any more.

|

| The band piece on this bra is very small to make up for its stretchiness (sorry for blur!) |

|

| You can see how strained this band is - unsurprisingly it is uncomfortable to wear, as it has reached its elastic limit and is starting to function like a "corset band". |

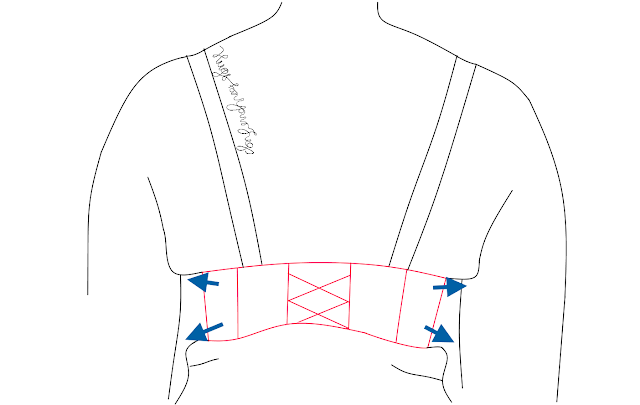

- If your band fabric is too stretchy to provide adequate tension, doubling the width of your fabric will immediately double the tension required to keep it the same length, and is a quick and easy fix when making a bra. In addition to this, for extra support, widen the band as much as possible - this increases the tension in a bra band too.

- However, if you are choosing a longline, consider one with an additional row of elastic directly below the underwires. Snug elastic here can provide a lot of friction at one of the most heavily loaded parts of the bra and help keep it snug against your body, and ensure that tension is maintained throughout the fabric of the band.

|

| This bra looks like a longline but has a nice snug band of elastic under the wires. This can be paired with elastic at the bottom of a longline band (not present here). Image edited for clarity. |

- Maintaining width throughout the bra's band is also good for support, increasing tension by increasing the force needed to strain it. This is why leotard backs (aka U backs) are popular in large cup sizes: the strap elastic is quite firm and stops the bra bunching up, allowing it to stay wide until the point of the strap closure. Note that due to the width of the fabric being integral to its strain you need to account for the lower part of the band stretching much further when designing it - you can see this issue on the stretchy black bra I posted above.

|

| A bra with a U back construction. See how the strap elastic helps to stop the band bunching |

|

| The U back's band stays very wide right until the strap attachment point, whereas the Standard back is considerably narrower here. |

- If your band fabric is too stretchy or a woven, don't expect to be able to counter that using snug elastic. While elastic itself can sometimes provide enough friction to support a bra, it often has to be so taut that it digs in uncomfortably because of how narrow it is. It's like wearing two very narrow bands instead of one wider one. This will put a lot of stress on your torso, digging in and causing bulging.

- In a similar vein, it is important to maintain an even tension between your elastic and band fabric. If the elastic is too snug, the elastic limit of the elastic is met when you put the bra on, and the band turns into two very narrow "corset bands", again causing that digging and bulging due to the high stress concentrations.

|

| The elastic is providing most of the tension (and thus most of the normal force) here |

Is Boning Pointless?

People seem to either love or hate boning in the side seams of their bras - I also see some people say it serves no purpose. While I understand finding it annoying or uncomfortable, it definitely does serve a purpose in the support system of a bra, especially in those with "standard backs" (as opposed to leotard backs). Boning helps to ensure that the band fabric maintains its width without bunching up, and overall maintains more even tension throughout the band. It can flex under pressure though and dig in at the top and bottom, causing pressure points and thus pain. It is not a necessary part of a bra's structure though, and can usually be removed without significant losses in support.

How do Moments Impact our Band Design?

You may recall that I went into some analysis on major moments within a bra in the extended edition of Part 1. I will go into analysing those moments and their impact on band design in the extended version of this one too. You can read both of these extended posts for £2 on my Ko-fi.

If you liked this post, be sure to follow me for email updates whenever I post a new one! If you really liked this post, donate to my Ko-fi for extra content!

*To any engineers reading this, I recognise that I'm implying here that stress causes strain, which is inaccurate, but I think this is the best way of explaining these concepts to a layperson.

**A user pointed out to me that I am misrepresenting corsets somewhat here, as corsets provide a great deal of their support by leveraging off the waist, the rigidity holding the cups up. This is of course true and I don't desire to alienate any readers who are more knowledgeable about corsets than me. This section of the post came about because I was thinking about stretch materials and maintaining tension, and I didn't think through the example clearly enough. However there do exist old garments that support the breasts in this way - such as short stays, which cover a much wider area on the body than a modern bra does.

Hi, I compliment you on an excellantly written post. I am also a lingerie designer, and cannot influence my students enough about "thinking" through the importance of the band & band fabric used. i will instruct them to read and pay for your posts.

ReplyDelete